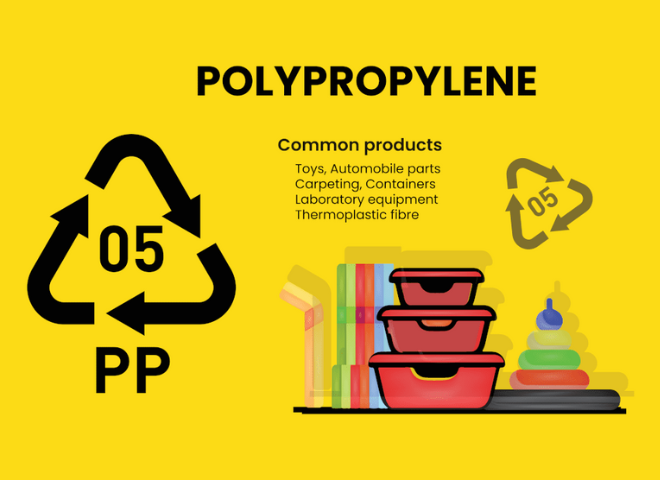

WHAT IS PP PLASTIC? ADVANTAGES, APPLICATIONS AND RECYCLING

Polypropylene (PP) is one of the most popular plastics in modern life thanks to its superior properties. With its chemical resistance, high durability and flexibility, PP plastic is increasingly widely used in many fields. In this article, Khang Anh Intercom will explore the advantages, important applications and recyclability of polypropylene plastic, helping you better understand this type of plastic and the benefits it brings to everyday life!

1. What is PP plastic?

PP (polypropylene) plastic packaging is an ideal packaging solution with many outstanding advantages. With its elasticity, high durability, good heat resistance and excellent tightness, PP plastic packaging has become the first choice for many industries, including food, pharmaceuticals, chemicals and other industrial products. This product not only protects the quality of goods but also ensures the safety of consumers, contributing to improving business efficiency.

2. Advantages and disadvantages of PP plastic packaging

Advantages of PP plastic packaging:

– High durability: PP plastic packaging stands out with its good impact resistance, effectively protecting the product inside.

– Tightness: The tight design helps prevent air and moisture, preserving the product for a long time.

– Reusability: PP packaging can be reused and recycled, contributing to reducing plastic waste.

– Low production cost: Compared to many other types of packaging, the production cost of PP packaging is significantly lower.

Disadvantages of PP plastic packaging:

– Difficult to decompose: PP plastic packaging is difficult to decompose and often cannot be recycled many times.

– Impact on the environment: The production and consumption of PP plastic packaging can have a negative impact on the environment, so solutions are needed to minimize it.

In summary, PP plastic packaging is a popular choice in many industries thanks to its outstanding advantages. However, to protect the environment, it is necessary to focus on solutions to minimize the negative impacts from the use of this packaging.

3. Applications of PP plastic packaging

Food boxes made from PP plastic

PP (polypropylene) plastic packaging is a versatile packaging solution with high heat resistance and durability. Thanks to its outstanding properties, PP plastic packaging not only protects products but also enhances brand value in many industries. Here are some common applications:

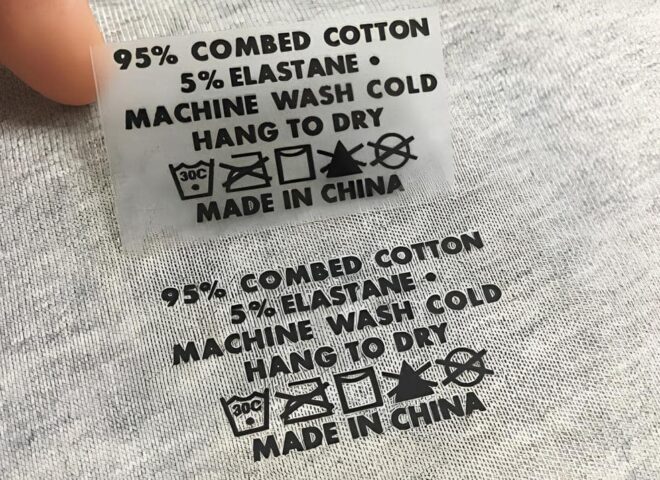

– Food packaging: PP packaging is often used to package confectionery, snacks, coffee, tea, spices and many other food products. With the ability to protect products from external influences, this packaging keeps food fresh.

– Medical product packaging: In the medical industry, PP packaging is used to package drugs, medical instruments and injection packaging. This material prevents bacteria from entering and protecting the product, ensuring safety for users.

– Chemical product packaging: PP packaging is an ideal choice for packaging detergents, lubricants and many other chemicals. Good tightness helps prevent leakage, protect the environment and ensure user safety.

– Electronic product packaging: PP packaging is also used to package phones, tablets and other electronic devices. High durability and impact resistance help protect products during transportation.

– Toy product packaging: PP plastic packaging is very popular in packaging children’s toys and entertainment products, ensuring attractiveness and safety for young children.

4. Recyclability

PP (polypropylene) is a popular thermoplastic that can be recycled, but the actual recycling rate is currently very low, only about 1%, mainly due to the following factors:

High recycling costs:

– The PP plastic recycling process is more complicated and expensive than producing new plastic.

– The cost of collecting, sorting and processing recycled PP plastic is also high, making recycled plastic less attractive to manufacturers.

Difficulty in collection and sorting:

– PP plastic is often combined with other types of plastic, making it difficult to collect and sort.

– Some types of PP plastic have colors or additives that make it difficult to classify by the naked eye, requiring advanced sorting technology.

Lack of market for recycled plastic:

– The demand for recycled plastic is still low, with many products requiring high quality that recycled plastic cannot meet.

– Lack of connection between recycled plastic manufacturers and recycled plastic product manufacturers.

Low public awareness:

– Many people are not aware of the importance of recycling plastic, leading to littering.

– Some consumers are concerned about the quality and safety of recycled plastic products.

Check out the recyclability of plastics here!

Conclusion

Although PP plastic is recyclable, the recycling rate is still low. To protect the environment and reduce waste, it is necessary to use PP plastic wisely. This includes reusing products, effectively sorting waste, prioritizing products made from recycled plastic, and participating in recycling programs.

PP plastic is a versatile material with many industrial applications due to its durability, chemical resistance, and heat resistance. However, disadvantages such as flammability and low UV resistance must be considered in some applications. By understanding the types of PP plastic and their properties, you can choose the right material for your needs.

Eng

Eng